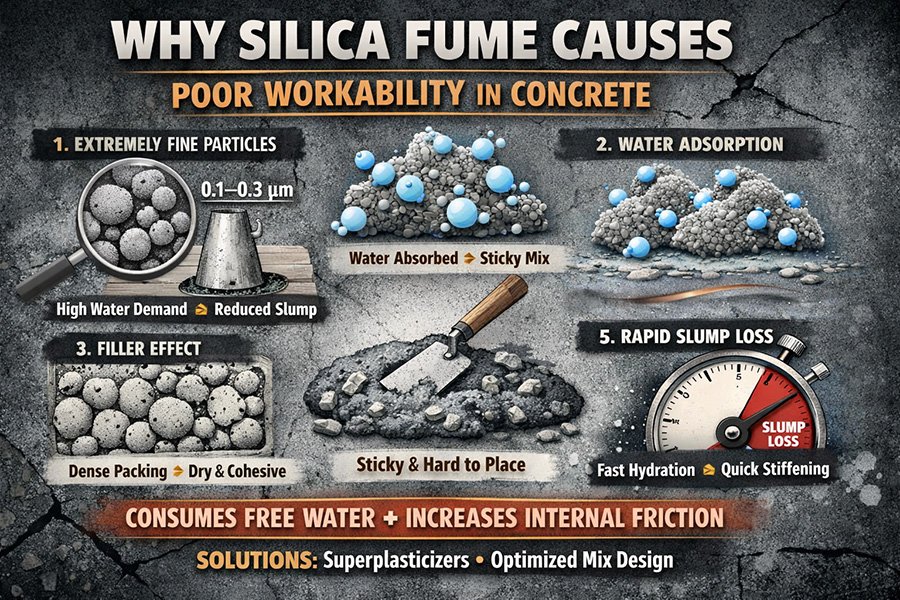

Silica fume is widely used to enhance strength, durability, and impermeability of concrete—but it is also well known for causing poor workability. This effect comes from several material-level mechanisms rather than a single factor.

Technical explanation

1. Extremely Fine Particle Size (High Surface Area)

Silica fume particles are about 0.1–0.3 μm, nearly 100 times finer than cement.

- This creates a huge specific surface area

- More water is required to wet the particles

- Free water in the mix is rapidly absorbed

Result:

➡️ Higher water demand → stiffer mix → reduced slump

2. Strong Water Adsorption Effect

Silica fume particles have:

- High surface energy

- Amorphous SiO₂ structure

- They physically adsorb mixing water onto their surfaces.

Result:

➡️ Less lubricating water between aggregates

➡️ Concrete becomes sticky and less flowable

3. Particle Packing & Filler Effect

Silica fume fills the microscopic voids between cement grains (micro-filler effect):

- Improves density and strength

- Reduces bleeding and segregation

However:

- Reduced bleeding means no surface water

- Internal friction between solids increases

Result:

➡️ Mix feels “dry” and difficult to place or finish

4. Increased Cohesion and Stickiness

Because of its fineness:

- Silica fume increases paste cohesion

- Aggregates are more tightly bound

Result:

➡️ Concrete becomes sticky, not free-flowing

➡️ Pumping and finishing become more difficult

5. Rapid Slump Loss

Silica fume accelerates:

- Early hydration reactions

- Formation of C-S-H gel

Result:

➡️ Slump loss occurs faster than in normal concrete

➡️ Workability decreases quickly after mixing

How to Improve Workability When Using Silica Fume

To counteract poor workability, concrete producers usually:

Use High-Range Water Reducers (Superplasticizers)

- Polycarboxylate-based admixtures are most effective

- Restore flow without increasing water–cement ratio

Optimize Silica Fume Dosage

- Typical dosage: 5–10% by cement weight

- Excessive dosage worsens workability

Adjust Mix Design

- Slightly increase paste volume

- Optimize fine aggregate grading

Use Densified or Slurry Silica Fume Properly

- Ensure good dispersion to avoid agglomeration

- Poor dispersion exaggerates workability problems