Micro-silica fume is a by product of high purity quartz, coke and sawdust reduction in the production of ferrosilicon or metallic silicon during the production of complex reactions in smelting. Among them, the quartz stone and carbon at 1750 ℃, the reduction reaction to produce unstable carbon monoxide, the temperature is higher than 2160 ℃, SiO gas containing gas sent to meet the air below 1100 ℃ with oxygen reaction to produce SiO2, after cooling The formation of high-fineness particles, the filter is collected by the filter is silicon powder.

Application area:

1) Concrete or Shotcrete

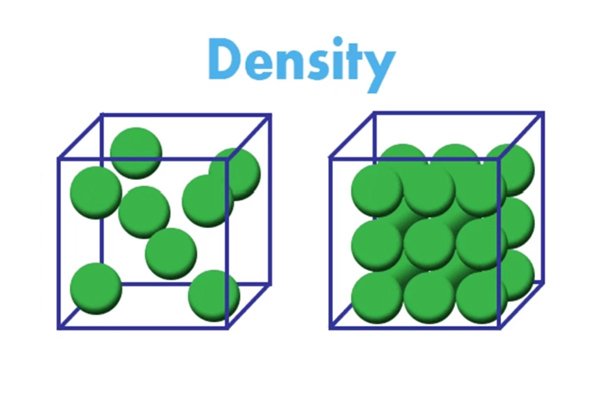

• Increase its density and strength, improve the performance on its durability,

impact resistance, corrosion resistance, anti-permeability and frost resistance etc

2) Refractory material & Ceramics material

• Greatly improve its density, strength and high temperature performance.

3) Cementitous Repair Products (Mortars & Grouts)

• Low permeability, increase resistance from chlorides, acids, nitrates and sulfate etc

4) Oil Well Grouting

• Increase durability and compressive strength, decrease permeability, better control of gas leakage

5) Concrete Tile, roofing & wallboard,panels

• Lightweight and improve the strength

6) Polymers & rubber product

7) other application, such as waterglass industry, thermal insulation material etc.

Microsilica 950 D is a dry powder microsilica admixture for portland cement concrete and mortars.

Microsilica 950 D is a pozzolanic material that consists primarily of fine silicon dioxide particles in a non-crystalline form.

Microsilica 950 D meets the requirements of ASTM C-1240 and contains a minimum of 95% silicon dioxide (SiO2)

Henan Superior Abrasives I/E Co., Ltd is one of the largest Silica Fume Suppliers in China, and also the premium source of high-performance Silica Fume products for concrete and refractory industries.

Welcome to visit our factory, if you have any question or any need, please contact us by Email sales@superior-abrasives.com or directly leave your message on the following form, we will reply you in 24h, thank you very much.