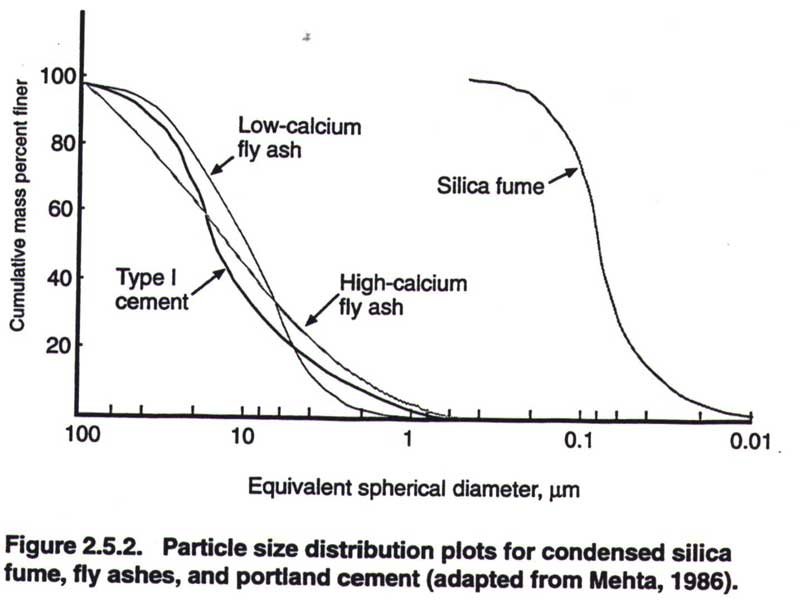

Self insulation block silica fume

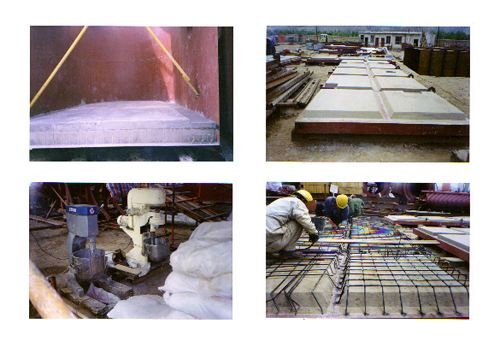

Composite insulation block is based on the current status of the new wall materials industry development, with high performance microsilica hollow block as shell, fill light thermal insulation materials such as foam micro silica fume powder or polystyrene foam, microsilica density and heat preservation material injection molding into the entirety and form silica fume block […]

Self insulation block silica fume Read More »