Composition:

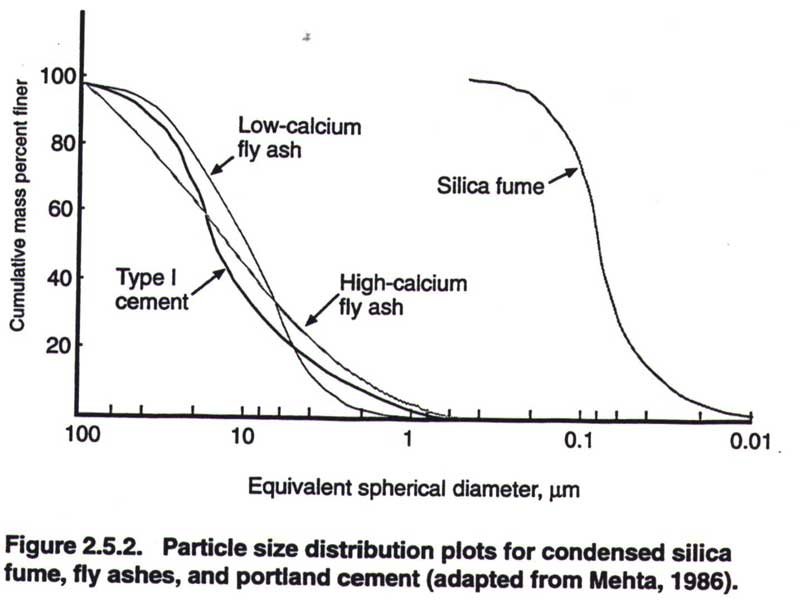

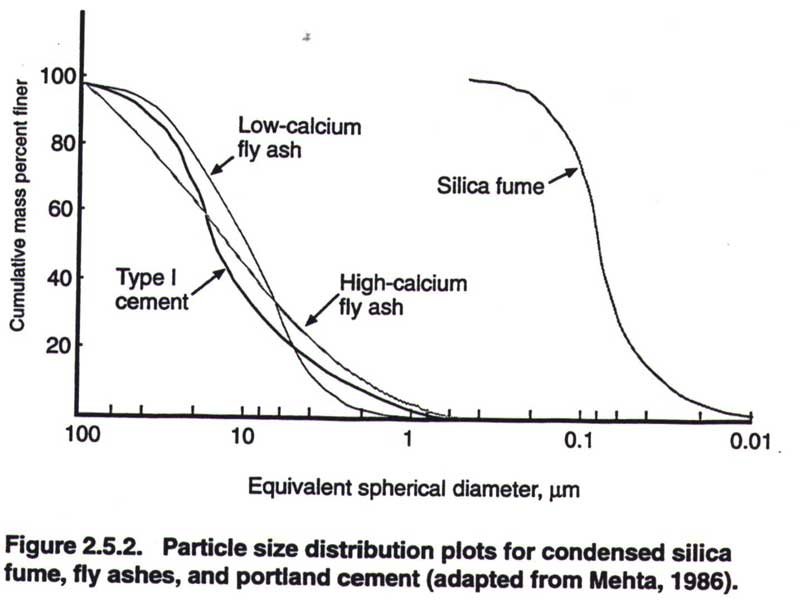

Condensed silica fume consists primarily of pure silica in non-crystalline form and contains more than 90% silicon dioxide. Small amounts of magnesium, iron, and alkali oxides are also present. Most particles are smaller than 1 mm with an average diameter of 0.1 mm. ASTM C 1240 limits the percent retained on the 45-mm sieve to 10%, the moisture content to 3%, and the loss on ignition (LOI) to 6%.

Condensed silica fume is frequently referred to by other names. Here are some of the other names for silica fume:

Condensed silica fume

Microsilica

Silica fume

Application of Condensed silica fume:

– Concrete.

– Cementitous Repair Products.

– Concrete Tile & Panels.

– FCB, Concrete Roofing & Wallboards.

– Shotcrete.

– Oil Well Grouting.

– Polymers & Elastomers.

– Repair Products.

– Refractory & Ceramics.

– Sustainability

Replacement:

Condensed silica fume is used as a replacement for portland cement. Silica fume can replace portland cement in the range of 9-15% by mass of cement.

Advantages

Using silica fume concrete creates the following advantages:

– Increased pore refinement

– Increased strength

– Stickiness

– Black/gray color

– Increased ASR resistance

– Increased sulfate resistance

– Consumes Ca(OH)2