Differences between fly ash, slag and silica fume

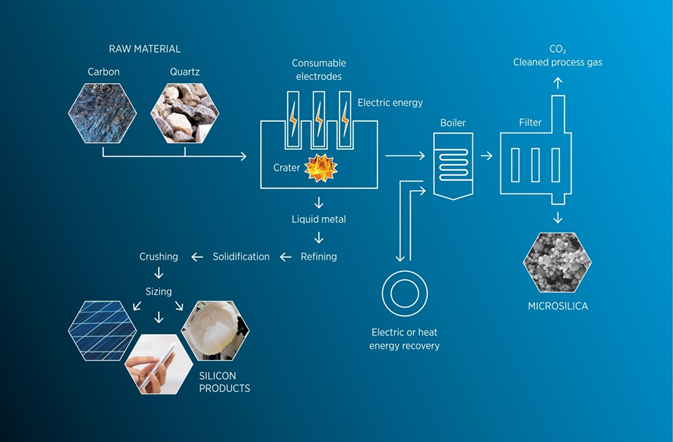

Supplementary Cementitious Materials (SCM) are added to concrete mixtures for various reasons including improving durability, decreasing permeability, aiding in pumpability and finishability, mitigating alkali reactivity and improving the overall hardened properties of concrete through hydraulic or pozzolanic activity or both. SCM are added to concrete in addition to or as a partial replacement of Portland […]

Differences between fly ash, slag and silica fume Read More »